“Pressure Profiling”

Unique features

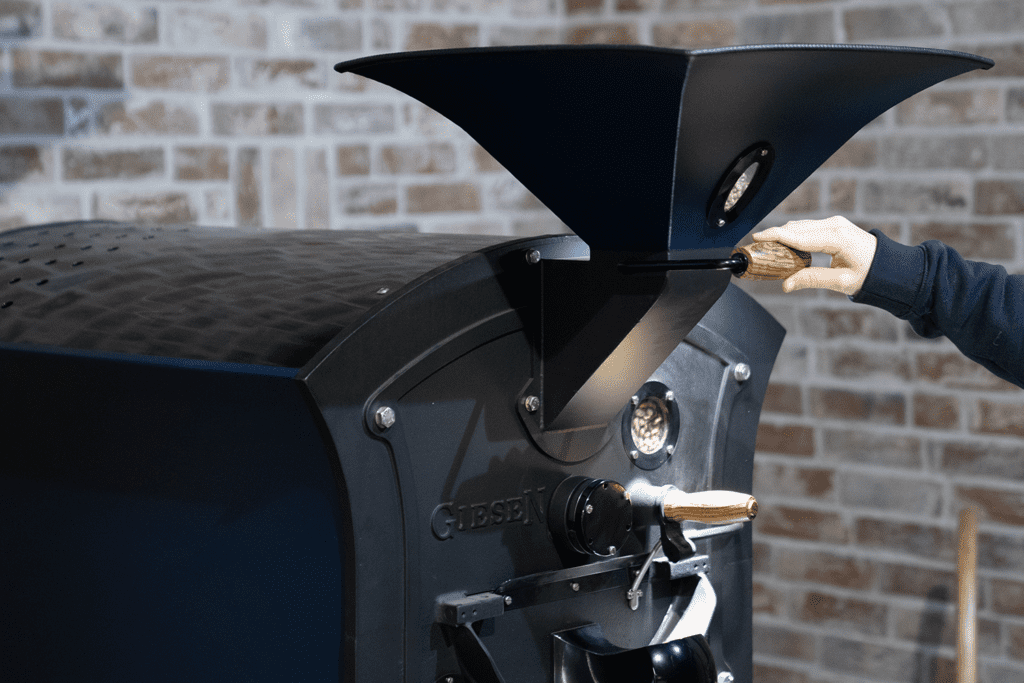

Many drum roasting machines share similar concepts in their design and function. Giesen machines come with unique features. In general, drum roasters feature a revolving drum and an impeller that continually draws air through the machine and through the drum itself.

The air intake is situated near the burners of the machine. The roasting chamber mixes the preheated air together with the coffee beans and the impeller evacuates them. The design of most drum roasters allows the roasting impeller to continually evacuate more air than the roasting machine is taking in. In simple terms, the roaster is always a bit out of breath. With the force of the roaster impeller, the machine collects chaff in the roasting cyclone and roasting exhaust (mostly smoke) is blown out through the exhaust stack.

Variable airspeed

Some roasting machines utilize the concept of variable airspeed. How does this impact the heat transfer? More air at higher temperatures can accelerate heat transfer and increase the Rate of Rise (RoR). More air at lower heat input levels, will slow down the heat transfer and decrease the RoR.

The impact on flavour works as follows: more airflow can accentuate the sweetness and brightness of the coffee; too much airflow can create sourness. Too little airflow will mute the acidity and potentially lead to leather-like or even smoky flavour notes. So, in theory, airspeed offers positive benefits but nevertheless, few roasting companies have embraced airspeed as a roasting parameter.

Airflow control

Giesen has taken airflow control to the next level by introducing the highly innovative concept of pressure profiling. How does it work? The control panel of basically all Giesen machines features a setting for “Pa” (which stands for Pascal), which is an expression of the underpressure in the coffee roasting system. By increasing the Pa setting, the machine will increase the rotation speed of the roasting fan to maintain a higher pressure target.

During the roast, the operator can increase or reduce the pressure setting to confirm the requirements of the profile. The Giesen Profiler can record and repeat this process with the next batch of the same profile. In my opinion, these features make Giesen roasters truly unique!

My next article about the exciting technology of pressure profiling will discuss specific roasts using the Giesen pressure profiling technology.

This Post Has 4 Comments

Should not be the opposite? To increase Pa, reduce rotation speed of fan

“The design of most drum roasters allows the roasting impeller to continually evacuate more air than the roasting machine is taking in. In simple terms, the roaster is always a bit out of breath.” this sentence explains how pressure works.

i think you are misunderstanding about the pressure in roasting system OR confuse about “inner bean pressure” with “drum pressure”. Dynamics are different, you think this is a pressure cooker but our drum and roasing system is not sealed system.

Is the airflow increase means pressure inside the drums increase too?

in my opinion, the pressure in the system increases when the exhaust fan speed is reduced and vice versa