Using airflow when creating roast profiles

by Willem Boot

Proper airflow through your roasting system is of the utmost importance for the accomplishment of roasting profiles. One of the key reasons why roasting profiles don’t work out is because the airflow might be obstructed due to basic cleaning procedures not being followed.

About airflow

Less airflow through your system will affect the ability of your roaster to transfer heat to the coffee. This, under almost all circumstances, will alter the flavor profile of your roasted coffee. Make sure you do a thorough cleaning of the chaff collector and of all the compartments where chaff and other roasting debris might collect after every roasting session.

Before you read on, make sure you check out the summary of our webinar on this subject. We did some hands-on experimentation with Drum Speed and Airflow and there was plenty of time for questions and answers. In addition to this, we did a live roasting session as well. Check it out here!

Willem Boot

How and when to clean?

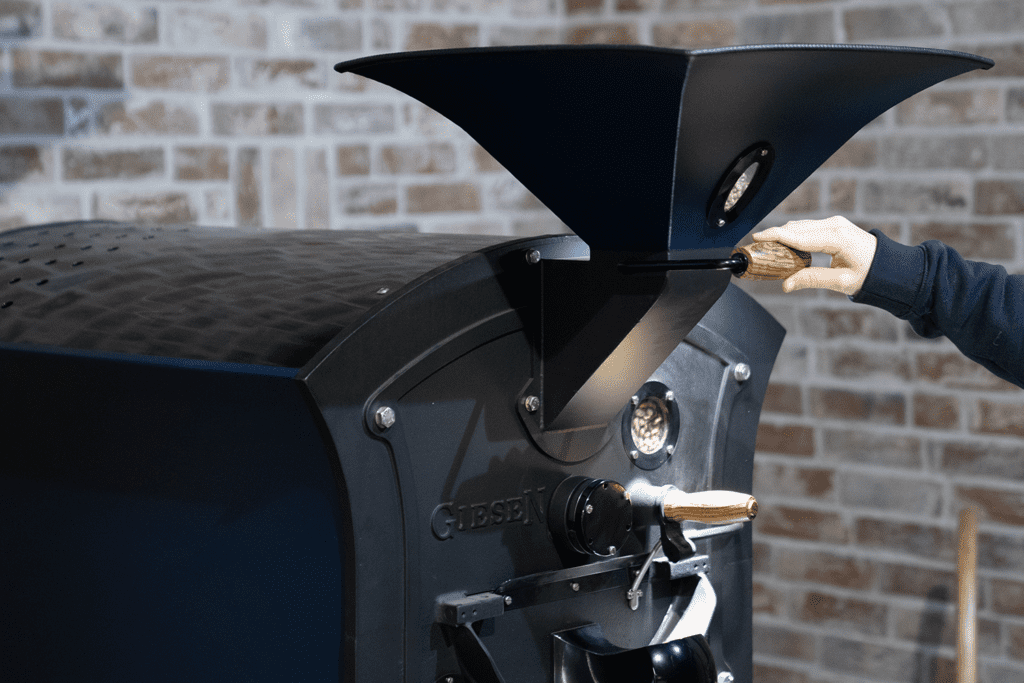

If your roasting session lasts more than 4 hours, then I recommend cooling down your machine halfway the day. Do a thorough cleaning by using a powerful semi-industrial vacuum cleaner. After every 120 hours of roasting it’s recommended to remove the cooling tray of your Giesen roaster. Clean out all the chaff that collects inside and under the cooling tray. I recommend the same procedure for all other brands of roasters. After every 500 hours of roasting, I recommend performing a deep cleaning of your machine by focusing on all the interior ducts of your roaster. After every 1000 hours of operation, you should clean all the exterior ducting of your roasting installation.

Airflow and Giesen roasters

Besides these essential cleaning procedures, I’d also like to address a unique airflow feature of the Giesen roasting technology. From the early days on, Giesen equips their roasters with airflow sensors that continually measure any fluctuations in airflow. This feature allows the machine to compensate for the possible loss of airflow. This by automatically increasing the output of the roaster fan. This is a unique Giesen feature. The current generation of Giesen roasters is also equipped with the ability to develop distinct profiles using air pressure as a profiling tool. In my next column, I will discuss the sophisticated Giesen roasting feature of air pressure profiling for the benefit of great-tasting coffee!

Best regards, Willem Boot

Monthly Giesen Webinar:

Join us live on every last Friday of the month at 09:00 Pacific Time (PT)

Or 18:00 Central European Time (CET).

Previous blogs and Webinars:

Blog #1: The moisture of Green Coffee Beans

Webinar #1: Video and text summary

Blog #2: The temperature setpoint option

Webinar #2: Video and text summary

Blog #3: Using the heat soak or heat shock technique

Webinar #3: Video and text summary

Blog #4: Creating profiles using drum speed

Webinar #4: Video and text summary

Esta entrada tiene un comentario

how to attend the next webinar , kindly send me the link