It’s quite challenging to imagine how to successfully complete a coffee roasting profile without the involvement of effective roasting software.

During the roasting courses at our campus, we often allow our students to experience how to roast without the use of software. I consider these sessions very helpful for the ability of candidate roaster operators. This is to develop an in-depth understanding of the temperature dynamics during the completion of a roasting profile. As I have observed so often, once students have experienced the challenge of controlling profiles manually, then the adaptation of roasting software becomes much easier to incorporate. Once you have learned about the real nuts and bolts of roasting profiles, then the customization and implementation of roasting software becomes much easier to comprehend.

Parameters to consider during roasting

First, the bean temperature. This is a direct reflection of the internal development of the coffee beans and of the chemistry changes that unfold during the roasting process.

Second, there’s the air temperature. This reflects the environment to which you expose the coffee beans. It is also indicative of the convection heat applied to the coffee beans.

Third, the Rate of Rise (ROR) is an expression of the rate at which the bean temperature is increasing over time. Often you calculate this is per 30 seconds. I usually like to compare the ROR to the speedometer of a car. A higher ROR is indicative of a profile that evolves faster. If the ROR is getting too low, then this points to the risk of the roasting process potentially stalling.

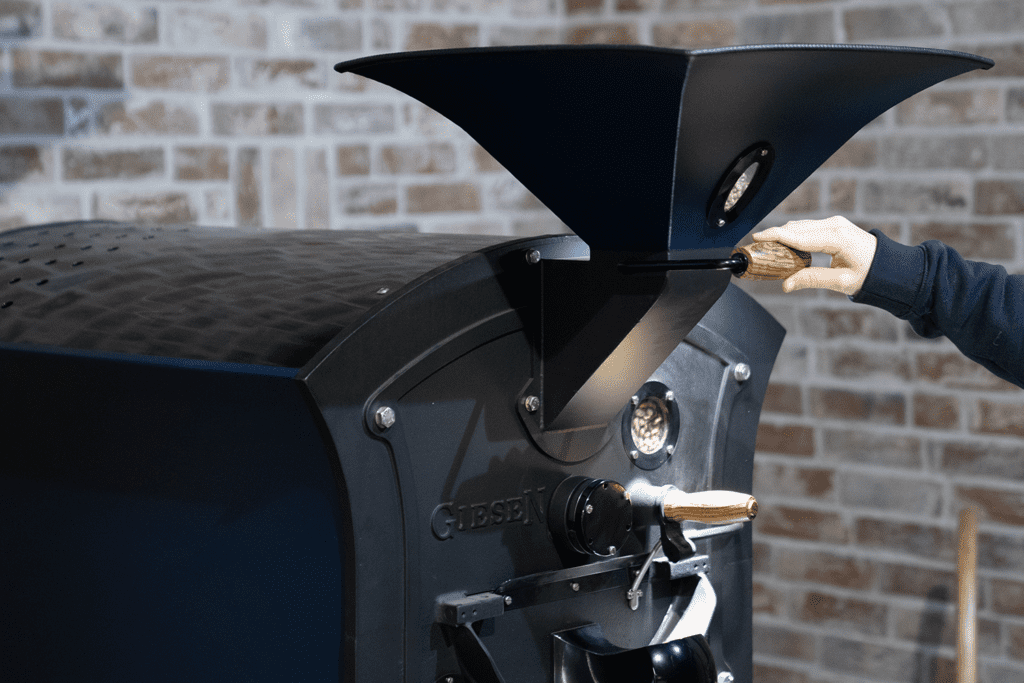

In addition, there are other parameters that can be very helpful to measure and observe. Giesen is the only coffee roasting machine brand out there with the ability to develop profiles using air pressure, expressed in units of Pascal (Pa). A higher setting of the Pa will facilitate more convection heat during the roasting process, while a lower Pa allows for more conductive heat. Finally, Giesen roasters offer the ability to control the rotation speed of the roasting drum. With all these sophisticated controls, it is key to understand how these parameters influence the resulting flavors in the cup. For this essential reason, I consider the involvement of reliable software as an important requirement to be able to obtain consistency and repeatability in the roasting process.

Unique Giesen software

Giesen Coffee Roasters started developing its proprietary software shortly after the introduction of the very first Giesen roasting machines. Some features of Giesen’s software are truly unique. Specifically, I’d like to mention the ability to automatically adapt profiles using so-called “triggers”. A trigger allows the operator to tell the roasting machine what changes the profile should make if certain conditions exist. For example, a trigger could be included in the roasting profile. This to automatically reduce the flame level of the burner if the ROR exceeds a certain critical limit. Additionally, the roasting machine can also be programmed to increase the Pa or air pressure setting. Do this once the bean temperature exceeds a certain level. Triggers offer unparalleled options for roaster operators to implement a superior level of intelligence in the design of roasting profiles.

Willem Boot

Willem Boot is a roasting consultant and trainer and founder of Boot Coffee Campus in San Rafael, California. He is also one of the Giesen Ambassadors. Visit www.bootcoffee.com.