This unique monthly Giesen webinar #3 hosted by Willem Boot cover topics like the perfect profile and how to achieve this. Together with live roasting sessions and exploring the features and functionalities of our coffee roasters and related equipment. What follows is the recording and a summary of the Giesen Webinar #3 of 31st of June 2020.

This webinar is recorded at the Boot Coffee Campus in California. Together with Marcus Young, the campus director at Boot coffee, Willem will help you unlock some of the misunderstandings and mysteries in roast profiling. Marcus and Willem together have half a century of coffee experience. They did a deep dive into roasting, quality management and cupping and continue to develop this.

What are we going to focus on in this Giesen webinar #3:

- Heat shock versus

- Heat soak

- Live roasting

Basic approaches in coffee roasting

The most common questions I get from roaster are: when do I start? How do I determine the benchmark that I’m creating? And how do I prepare unique profiles that set my coffees apart?

In the last webinar we covered principles of heat transfer during coffee roasting. Click here to watch the previous episode or read an extensive summary.

There are five distinct parameters to control the profiling on a Giesen roaster:

- Charge temperature

- Temperature setpoint

- Heat supply

- Pressure in Pa

- Drum speed in Hertz or RPM

In this webinar we’re looking closer at the charge temperature and the heat supply parameters. With Giesen roasters, we have the ability to follow the rate of rise. The RoR is the bean temperature increase per 30 seconds which is continually calculated. The higher the RoR, the faster your bean temperature will increase.

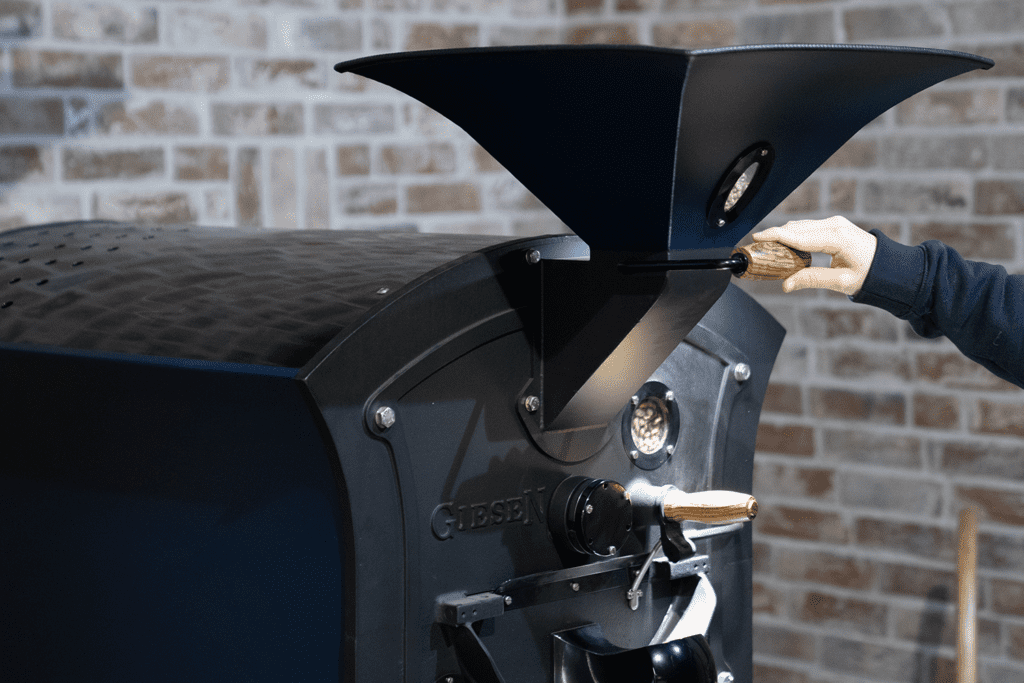

Today’s roasting trial will be on the sample roaster.

Heat soak profile:

In a heat soak profile, you’re allowing the coffee beans to absorb the radiant heat from the drum, up until the point of creating an endothermic reaction. This point is called the turning point in a roast.

Be very gentle with the temperature and your heat supply in the initial phase of the roast. In this particular roast there was no heat supply for the first minute and a half. When you’re ready to add more heat, do this gradually. In this example we increased the power to 40% and then to 80%.

When to use heat soak?

- The coffee density

- If your coffee has a low density you could benefit from doing a heat soak.

- A fresh harvest

- A freshly harvested coffee can still have relatively high-water activity. And doing a heat soak can be beneficial. This is actually part of a larger discussion on how moisture is distributed in the cellular structure of the coffee. But by using the heat soak technique, the distribution of the moisture will be evened out.

- Very delicate coffees

What is heat shock?

Much higher charge temperature, previously we were using 300 – 320 Fahrenheit and in this heat shock profile we are using 380 Fahrenheit as a charge temperature. We also used a lot more heat supply, 60%. And we kept it at that level and then we started decreasing it.

The difference with a shock profile

- The higher charge temperature

- Upon charging we applied more heat

The coffee & differences

The coffee: Finca la mula washed

Moisture: 10.2%

Density: 72 kg / hl

|

Value |

Heat soak |

Heat shock |

‘Aggressive Soak’ |

|

Charge temp (air) |

380 F |

375 F |

390 F |

|

TP |

00:55 |

00:52 |

00:52 |

|

FC |

07:20 |

07:10 |

06:25 |

|

Endtime |

08:45 |

08:30 |

08:10 |

|

End temp (beans) |

380 F |

380 F |

375 F |

Live roast

Heat soak profile with a higher charge temperature but still containing the benefits of the soak.

Question and answer:

Q: When your roaster is showing 0% on your burner do you have to completely relight at the turning point?

A: If you have a low flame level during the heat soak, you do have to gradually increase the power.

Q: When you say that you charge with 390 F, do you mean air or bean temperature?

A: When I mention the charge temperature, I always mean the air temperature.

Q: What size Giesen are you using for these trials?

A: We are now using the WPG1.

Q: What do you suggest when you cannot hear the first crack? Usually I cannot hear the first crack while using a Giesen W6A?

A: This is a challenge for all roasters because there is always a lot of background noise while roasting. But what I would suggest is to create a reference point so that you’ll know when you can expect the crack. Or what I see other roasters do is use a stethoscope or headphones. It really comes down to having a quiet enough space to hear it.

Q: Is there any reason why you are not experimenting with the drum speed or pressure during these trials?

A: Try to follow a more scientific approach to keep your measurements the same. Otherwise you cannot compare different roasts to each other. So, try to change only one variable per roast. When you cup you will know what kind of impact the change had on your coffee.

The next webinar is on 28th of August, which will take place during Willem’s visit to the Netherlands and will feature all kinds of exclusive Giesen content.