Whether you work with the Giesen Profiler or that you roast without sophisticating software but with pen and paper. It’s important you know how to build roast profiles from scratch and how to strategize the development of your roast profile. In this Webinar, Willem Boots tells you everything about it.

The topics of this webinar are:

- How to build roast profiles from scratch

- How to strategize the development of your roast profiles

- Coffee roasting defects

There are various roasting software options available. As I mentioned, Giesen has wonderful software named ‘Giesen profiler‘ and there is also other software. The difference between the Giesen software, versus the others, is that with the Giesen you can not only record your profile but you can also manipulate these profiles. Besides that, you can allow them to replay what you have accomplished before.

How to build roast profiles from scratch

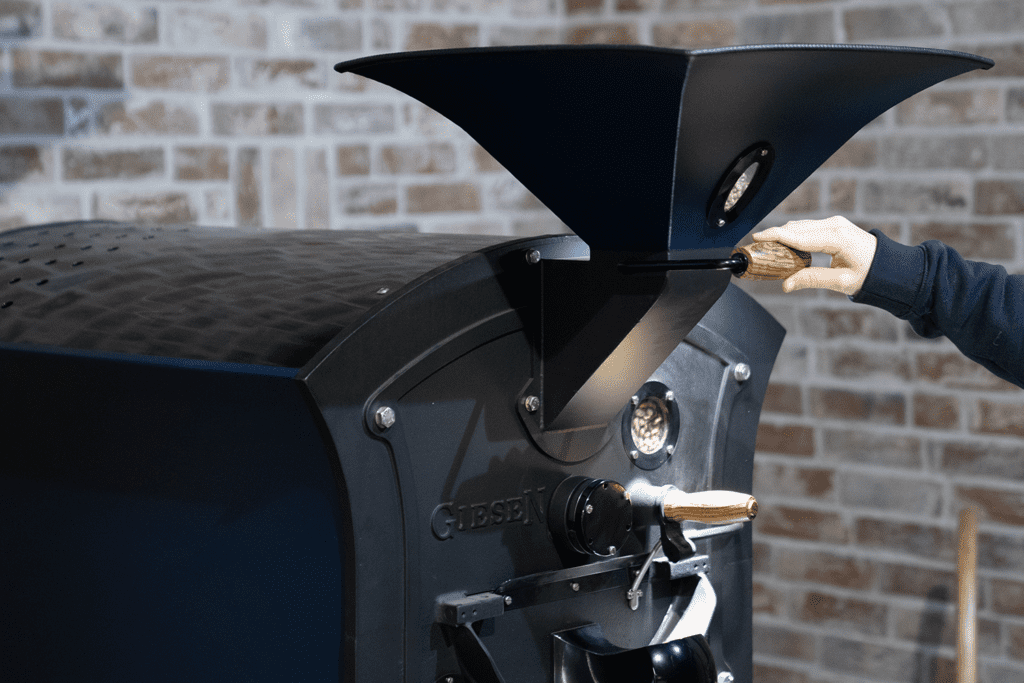

When you begin the roast, the product you start out with is washed green coffee beans. After that, there are some milestones you can recognize. Below, we share them with you. Note: The temperatures in your machine can be different. Our temperatures were in the middle of the Giesen W1A and Giesen W6A.

The milestones:

- Milestone 1: smell of freshly cut grass, 272 degrees (Fahrenheit), time: 4:10 minutes

Between the start of the roast and the moment you smell freshly cut grass, the beans gradually start absorbing heat at the point where the internal temperature of the beans exceeds water. The water vapor that starts developing now induces the first phase of the chemical transformations in the beans. Water vapor starts building up pressure and that pressure starts to induce the milliard reaction.

- Milestone 2: smell of hay, 300 degrees (Fahrenheit), time: 5:30 minutes

The hay smell is the sign of the ongoing development of the Milliard reaction. The beans are changing color; the browning occurs. This is the early start of caramelization. Coffee has a complex set of sugars and the caramelization is indicative of the fact that these sugars are transforming.

- Milestone 3: the ‘A’ point, 354 degrees (Fahrenheit), time: 7:50 minutes

This milestone occurs just before the first crack, it’s the precursor. It’s the point where the oils in the bean start becoming volatile. The actual coffee aroma can proceed. Therefore, the ‘a’ in ‘A’ point is for aroma. At this stage, we see the beginning of the exothermic reaction. This is where heat starts to come out.

- Milestone 4: first crack is almost finished, 387 degrees (Fahrenheit), time: 10:15 minutes

Now we are well into what we call the roast development. The development cycles. The cycle starts at the early onset of the first crack and continues until you finish your roast. You can see color changes and smell a distinct coffee aroma.

- Milestone 5: roast is finished, 393 degrees (Fahrenheit), time: 11:20 minutes

How to strategize the development of your roast profiles

There are some helpful concepts to strategize the development of your roast profile with. We share two of them with you.

Concept 1: the mid point temperature. It is the temperature in the middle of your first crack- and second crack temperatures. This usually represents a sweet cup of coffee with enough of those browning reactions and caramelization. Even if you are roasting lighter or darker than the mid point, this can be a useful referent to have. It can be helpful with finding the typical bach size and understanding your roaster.

Concept 2: the roast development time. It’s the time between the first crack and the end of your roast. The darker you are roasting, the longer the development time will be. Sometimes it’s easier to convert to seconds. For example, when you are roasting manually. This concept can be important in order to consistent.

Coffee roasting defects

We discuss some roasting defects and how to prevent them.

- Uneven moisture evaporation

This can be indigestion for the fact that the initial heat applied to this coffee was too much to handle. If the beans themselves are relatively fresh crops, it is possible that water vapor moisture starts to excite the beans more in one site of the bean than the other side. The prevention is to treat this specific coffee more like a softer bean.

- Scorching

You see burned marks around the center cut of the bean. The service of the bean slightly burned because of the drum being too hot.

- Tipping

The sides of the bean get burned. This indicates that the beans were rotating in the drum in such a way that the sides were touching the hot spots of the drum. Could be an issue with the roasting drum itself but it could also be the fact that the roaster develops centrifugal forces which allows the beans to be pushed more towards the drum itself. This can lead to tipping.

- Initial temperature too high

In this case, a softer bean gets treated as a harder bean. The bean is expanding much faster than the structure of the bean allows. And this easily leads to a roast profile that can be overdeveloped. The beans are bursting out of their jackets.

Learn more about softer and harder beans? Watch the webinar.

- Bean fracture

These fractures were probably already there pre-roasting. In the roasting process, a small chip pops out of the service of the bean and the viper structure underneath starts burning. There are various causes for this defect to occur.

- Internal scorching

Inside, one side of the bean will be more roasted than the other side. This can be costed because of to much heat or uneven moisture.

More information on how to strategize the development of your roast profiles? Check out the webinar video!

Check out the other Giesen blog articles and webinar summaries here.