Last webinar #14 focused on roast safety & fire prevention. Willem and Valerian talked about everything you need to consider to roast safe. What did they learn over the years? We wrote a summary of it.

We are looking at safety in a wide context. So we are not just looking at safety equipment, but also safety from a product/ liability and personality side. Also, I want to take the opportunity to help you become more aware of common safety issues and how we can proactively work to prevent safety situations.

Key areas of safety

There are four key areas of safety. The two key areas that always need to be the first priority are our personal and employee safety and product safety. This means you want to keep the products plus the consumers of your products, safe from harm, injury, or illness. Roasted coffee, is nog in the highest class where product safety can be a real issue. Even if coffee gets very old, besides the fact that it starts tasting nasty, it doesn’t necessarily develop bacterial wild growth. But if you produce, for example, cold brew coffee of cappuccino, it is important to look at bacterial wild growth too.

The four key areas of safety:

- Personal safety: keeping your staff safe and free from harm or injury.

- Product safety: keeping your products, and those that consume your products, safe and free from harm, injury, or illness.

- Equipment safety: keeping your equipment clean, maintained, and safe to operate.

- Coffee roasting facility safety: keeping your facility clean, safe, and compliant with the law.

A lot of these safety issues could be dealt with good logical thinking. This is something you should always keep on doing to protect yourself, your employees, and your business from big safety issues.

Roast safety plan

When it comes to the layout of your roastery, it’s important you think about the different areas you need. Also because of the safety requirements. You will want to think of an area where you store your green coffee beans. That storage area should meet certain requirements for safety because green coffee bags are heavy. If there stacked on top of each other, they could become a hazard. And from a lifting perspective, there can be potentially personal hazards. Besides that, the green coffee storage area should be thought of as a separate area, also from a quality perspective. This way you can ensure that the conditions are right for the quality of the coffee beans. You also need to think about the safety issues in the roasting area itself. This is the place where a lot of situations can happen, think of the temperatures at which we roast. Then, there is the area where packaging good is stored, these materials are often very fire-sensitive. It’s important you think of where to store this packaging.

So, applying some good logic to the layout of your facility really helps you with requirements and needs to make a safe roasting facility.

Valerian: ‘When it comes to the layout of the roastery, we went to the inspection and asked if they could advise us with building our roastery. So, before we lay out the hole roaster, whey asked the help of the inspection. That’s a smart tip.’

Fire safety protocols

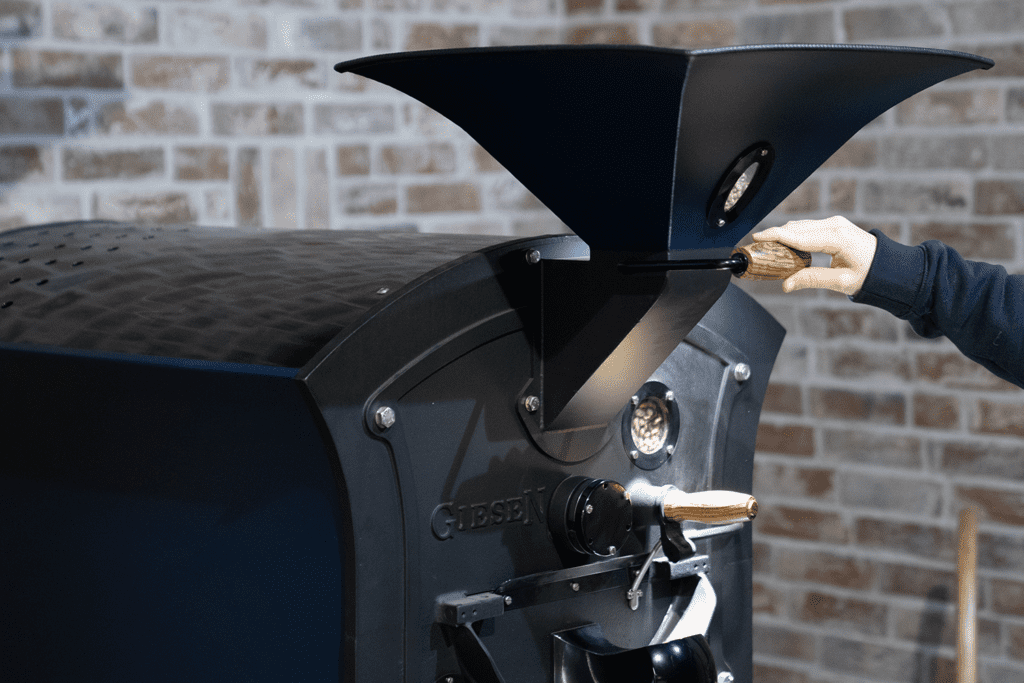

It is always important to see how many opportunities there are for fires. Even when you think that you successfully cleaned out your roasting machine and thought about roast safety. It is essential to really understand how your machine is made up. How it’s assembled to understand where issues can occur. I want to address our fire safety protocols that are key to embrace for your roaster:

- One of the key ingredients for a possible roasting fire is the chaff, which you can find in the chaff collector. If the chaff collector is not cleaned consistently, at some point, the chaff will start a fire.

- Pointing at the cooling area. If you remove the cooling screen, you will find a lot of chaff billed up.

- Make sure you keep the burner chamber clean. That is usually the place where chips and chaff starts traveling through your roasting system and costs some sort of fire.

- A lot of near-fire situations can be dealt with a small water sprayer. This works very simply and can even be applied through your sampler. This way, you spray a very small amount of water into your roasting drum. And this will displace the oxygen which can then help you to put out the threat of a fire.

Fire distinguisher

If things get out of hand, you obviously need a fire distinguisher. We advise two types. The first one is a foam distinguisher, which should be applied if things get out of hand. The other one is the CO2 liquid distinguisher. Which will display oxygen and cool down the situation. But obviously, you will not want to get there. So what are some of the right steps to consider if a fire is occurring? At all times, you want to take away the cause of the issue. Which in many cases, you have to think of preventing any more gas from flowing through your roaster. So having a gas-off switch near your machine is really helpful.

Like to know everything about roast safety? Watch the webinar #15.

Check out the other Giesen blog articles and webinar summaries here.