“I know what I want: W140A”

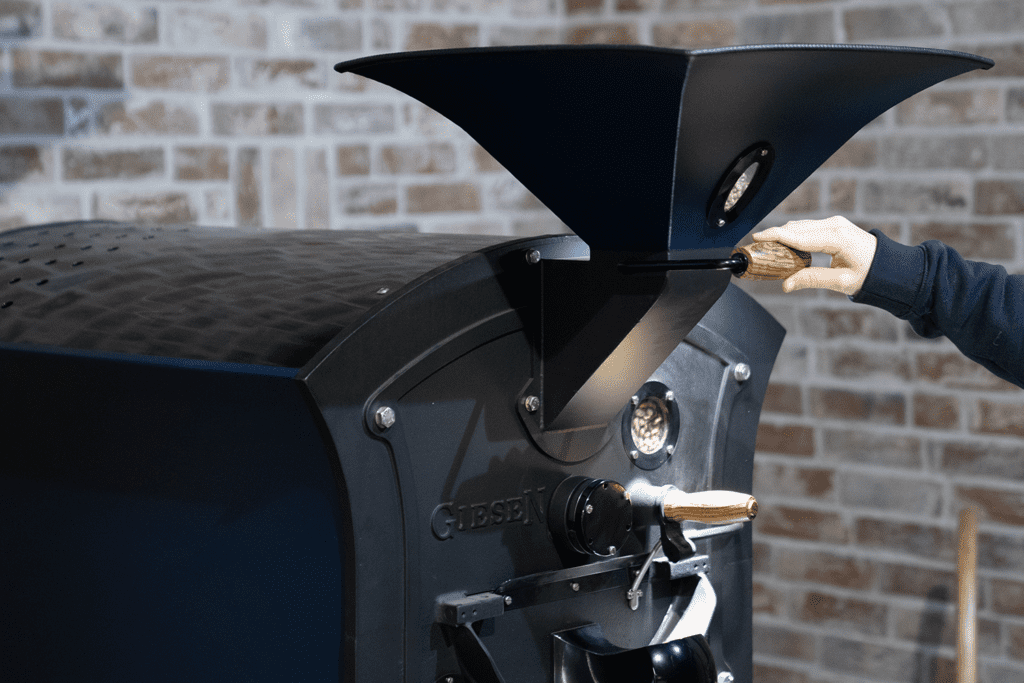

A conversation with Wilfred Giesen about the W140A.

For the release of the new big coffee roaster, we decided it would be interesting to interview Wilfred Giesen, the CEO of the company.

Wilfred, the W140A is finished now, how long did it take to design and build it?

We have been working on the roaster for about a year. There is more to it than just building the machine. It is the idea that must be worked out. Don’t forget about everything that is attached to the machine. The destoner, the conveyor system, the after burner with heat recovery system and the air conditioning system.

Did you need to change your plans much during the development process?

Some minor tweaks but nothing major. We needed to test all new features extensively and the first results are very positive.

Was there anything less positive during the development.

The cast iron plates at this size are quite heavy and take longer to produce. That makes the process a bit slower than with a smaller coffee roaster, but nothing we can’t handle.

How many people worked on the new roaster the last 12 months?

About 6 to 8 people. Not every person was working on it every day of course, but on average.

I heard you personally worked on the W140A too. What did you do in the process?

I came up with everything and explained the vision I had of the machine. I know what I want, but the guys here make it.

Which feature of the coffee roaster would you like to emphasize?

The W140A is very controllable, especially for a coffee roaster of this size. The accuracy is due to the adjustability of all the parts of the roasting process. The possibility to control that much in a roaster this big is quite unique.

When can the W140A be ordered?

Starting right now the W140A can be ordered.